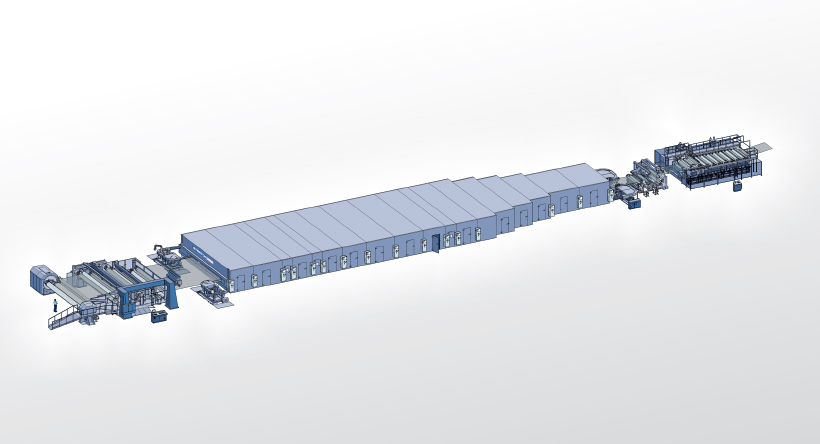

Our customers get the stretching technologies and services for an efficient production of numerous BOPP film types for a wide variety of applications: Whether high output lines for Commodity Films or Special lines for Special Films such as Tobacco Film, High Barrier Films, Synthetic Paper and many more.

For the high-yield production of specialty multilayer film with 3.5 or more layers for attractive high-margin markets, we offer tailored solutions for stretching equipment for value-added applications Ultra High-Barrier Film, Various Label Types, High-Speed Form Fill-Seal, Over Wrapping and many more.

| Film Types | Thickness Range |

|---|---|

| Plain film | 12 - 50 μm |

| Heat sealable | 15 - 40 µm |

| Metallisable Film, Label Film | 15 - 40 µm |

| White Opaque Film | 25 - 50 µm |

| Plain Film for Adhesive Tapes | 25 - 40 µm |

| Cigarette Film | 20 - 22 µm |

| Matt Film | 18 - 40 µm |

| Cavitated Film Density |

25 - 80 µm 0.65 g /cm3 |

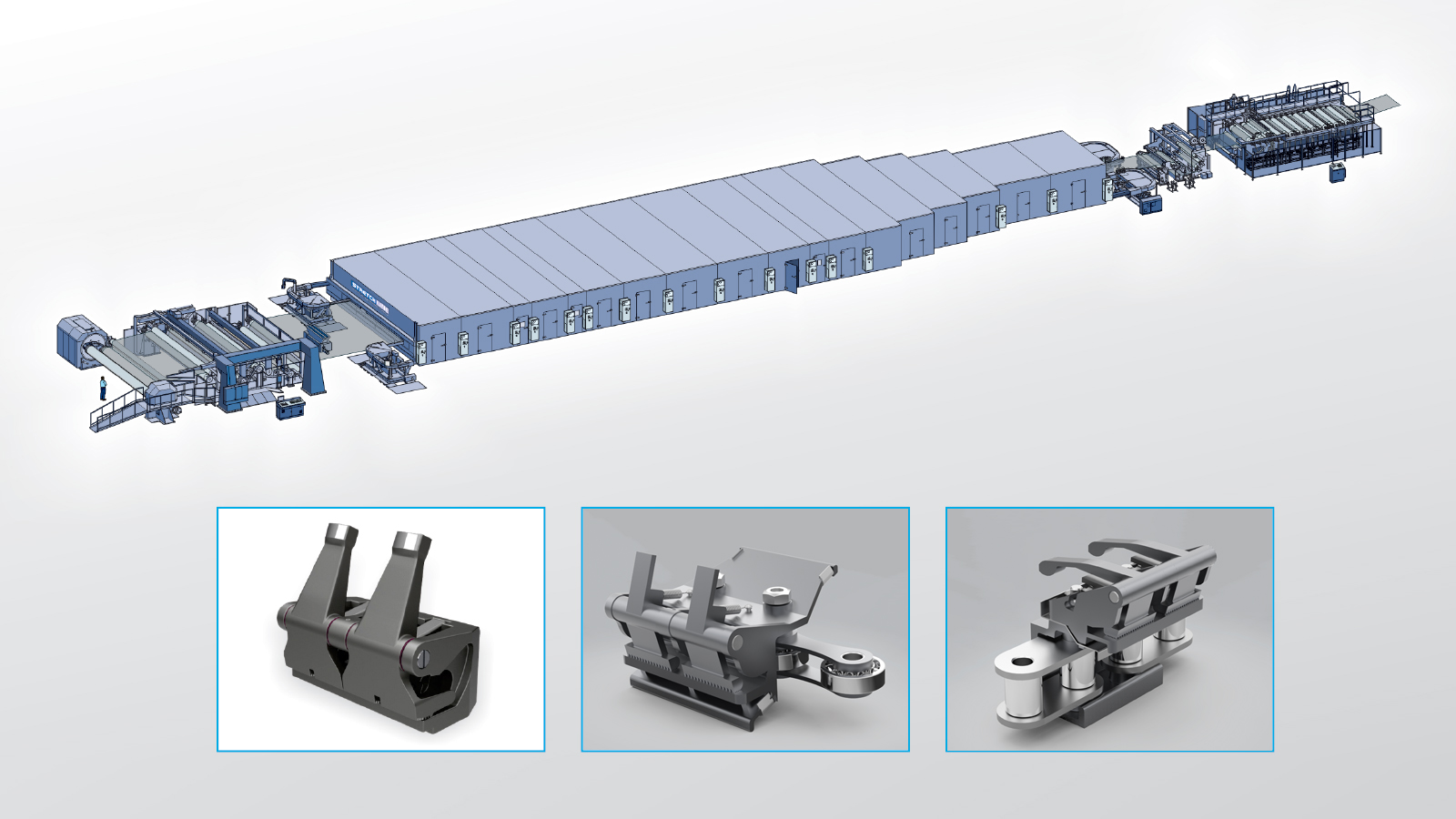

World Wide Suppliers of Key Spare Parts, Assemblies, and

Equipment for BOPP, BOPET Film Lines