SLEEV, FLANGED AND THRUST BEARINGS ARE AVAILABLE IN THE STANDARD MATERIALS RULON® AR, LR AND J, THROUGH OUR DISTRIBUTION CHANNELS.

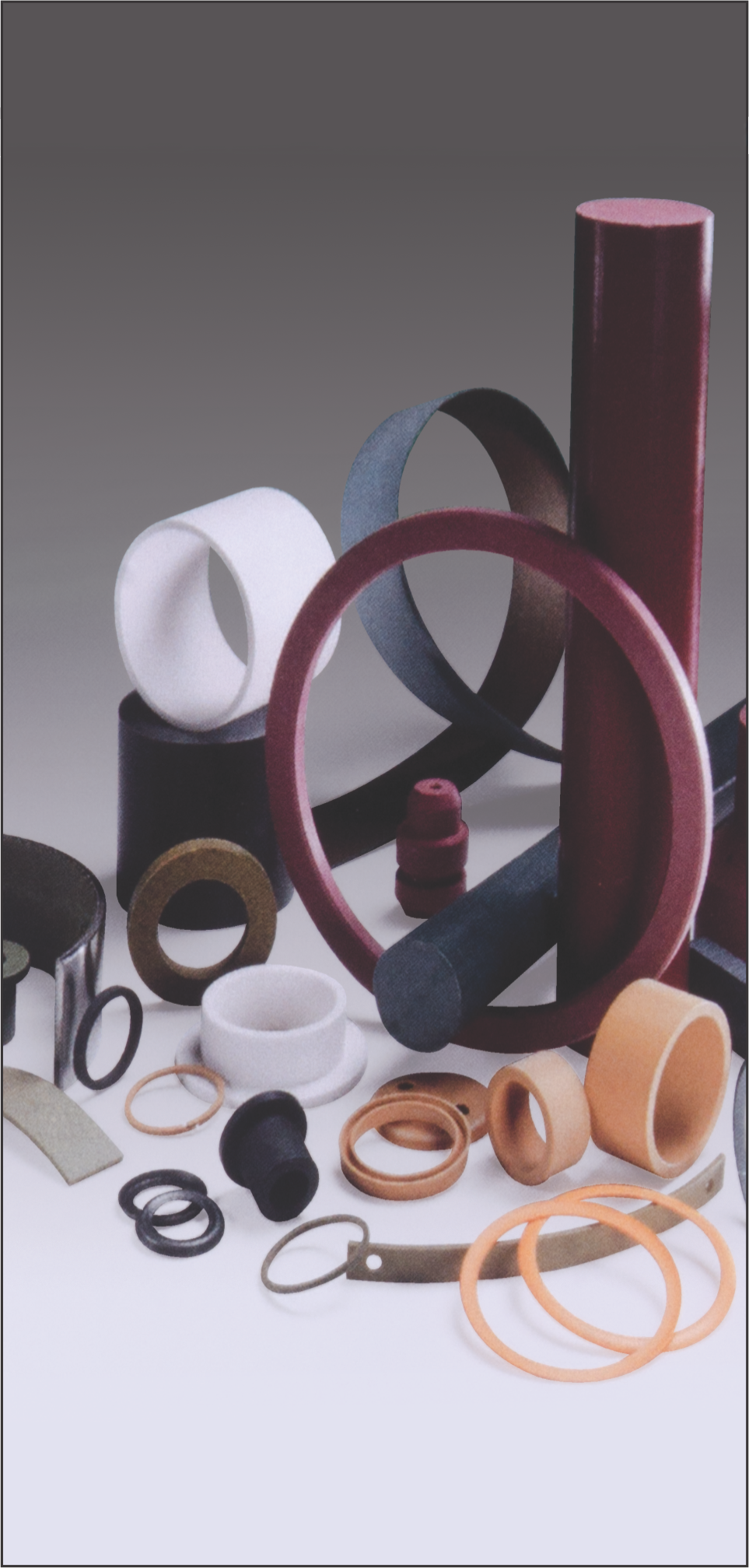

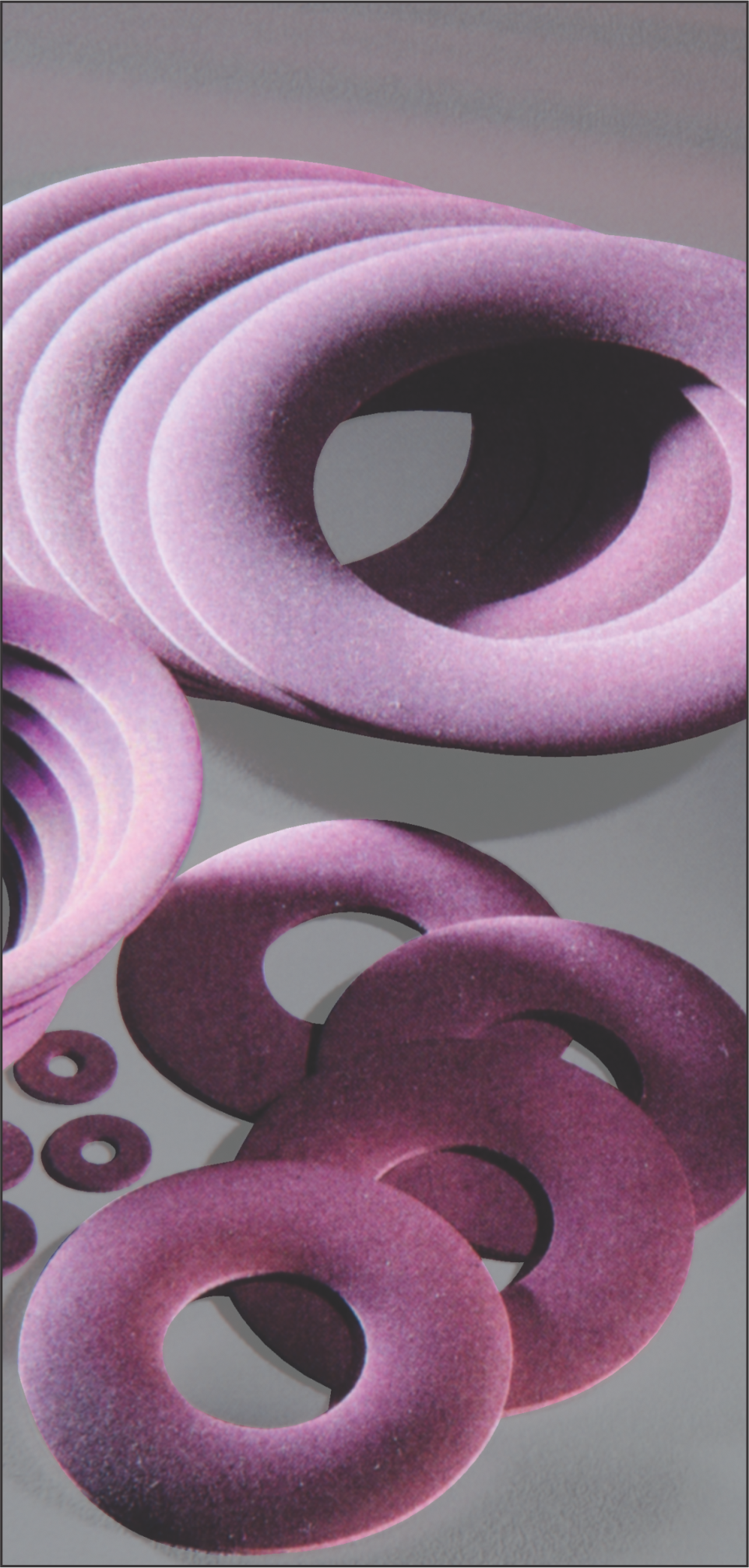

WEAR COMPONENTS CAN TAKE A VARIETY OF SHAPES AND SIZES, OTHER THEN THOSE DESCRIBED ABOVE. THESE CAN ENCOMPASS THINGS SUCH AS WEAR BANDS, PUMP BODIES AND PISTONS FOR CHEMICALLY AND THERMALLY DEMANDING ENVIRONMENTS. THESE ARE USUALlY MANUFACTURED TO YOUR SPECIFICATIONS OR 'FOURWENTS' CAN ASSIST YOU IN THE DESIGN. FOR FURTHER DETAILS, PLEASE CONTACT OUR SALES DEPARTMENT AT sales@fourwents. com

| DESIGN CRITERIA RULON® AR | |

|---|---|

| Temperature - Typical Range F0 ( c0) | -400/+550 [-240/+2881* |

| Maximum PV [ Continuous)(MPa*m/s) | 1 0,000 m(0. 35)* |

| Maximum P - psi ( Static )(Mpa) | 1000 (6.91)* |

| Maximum V- SFM [ No load) (m/s) | 400 (2)* |

| Shaft Hardness - Minimum | Rc35 |

| Shaft finish recommended Ra in[µml | 8 -16 (0.2-0.4)* |

| Shaft Material | Steel | ENGINEERING INFORMATION |

| Friction - Static & Dynamic | 0.15- 0.25 |

| Water Absorption ASTM D570 | 0% |

| Flammability ASTM D635 | Non-Flammable |

| Chemical Resistance | Inert |

| Thermal Conductivity | 2.3 (0.331)* |

| BTU/hr/sq. ft./ "F/ in. (W/m*K) | Diameter 4. 8 [8. 61* |

| Linear Coefficient of 78"-300"F Thermal Expansion [ 26" to 149" C I x1 0-5in/in"F [ x10-5m/m"C I | Length 6.2(11.11)* | PHYSICAL DATA |

| Elongation ASTM D4894 | 175% |

| Tensile Strength ASTM D4894 [MPal | 2000 psi (13. 81)* |

| Deformation ASTM D621 | 5% ( 1500psi-24hr. RT ) |

| Specific Gravity ASTM D792 | 2.22 |

| DESIGN CRITERIA RULON® LR | |

|---|---|

| Temperature - Typical Range F0 ( c0) | -400/+550 [-240/+2881* |

| Maximum PV [ Continuous)(MPa*m/s) | |

| Maximum P - psi (static)(MPa) | 1000 (6.9)* |

| Maximum V -SFM (no load)(m/s) | |

| Shaft Hardness - Minimum | Rc35 |

| Shaft finish recommended Ra in(µm) | |

| Shaft Material | Steel | ENGINEERING INFORMATION |

| Friction - Static & Dynamic | 0.15- 0.25 |

| Water Absorption ASTM D570 | 0% |

| Flammability ASTM D635 | Non-Flammable |

| Chemical Resistance | Inert |

| Thermal Conductivity BTU/hr/sq. ft./ "F/ in. (W/m*K) | 2.3 (0.33)* |

| Linear Coefficient of 78"-300"F Thermal Expansion [ 26" to 149" C I x1 0-5in/in"F [ x10-5m/m"C I | Diameter 5. 1 (9. 2)* Length 5.9 (10.6)* | PHYSICAL DATA |

| Elongation ASTM D4894 | 150% |

| Tensile Strength ASTM D4894 [MPal | |

| Deformation ASTM D621 | 3% ( 1500psi-24hr. RT ) |

| Specific Gravity ASTM D792 |

| DESIGN CRITERIA RULON® J | |

|---|---|

| Temperature - Typical Range F0 ( c0) | -400/+550 (-240/+288)* |

| Maximum PV () Continuous)(MPa*m/s) | 7,500 (0.26)* |

| Maximum P - psi ( Static )(Mpa) | 750 (5.2)* |

| Maximum V- SFM [ No load) (m/s) | 400 (2)* |

| Shaft Hardness - Minimum | Rb25 |

| Shaft finish recommended Ra in(µm) | 8-16 (0.2-0.4)* |

| Shaft Material | 316 S. S. & Non-Ferrous | ENGINEERING INFORMATION |

| Friction - Static & Dynamic | 0.12- 0.20 |

| Water Absorption ASTM D570 | 0% |

| Flammability ASTM D635 | Non-Flammable |

| Chemical Resistance | Data Available |

| Thermal Conductivity BTU/hr/sq. ft./ "F/ in. (W/m*K) | 1. 7 (0.24)* |

| Linear Coefficient of 78"-300"F Thermal Expansion [ 26" to 149" C I x1 0-5in/in"F [ x10-5m/m"C I | Diameter 5. 2 (9. 3)* Length 6. B (12. 2)* | PHYSICAL DATA |

| Elongation ASTM D4894 | 180% |

| Tensile Strength ASTM D4894 [MPal | 2000 psi (13. 8)* |

| Deformation ASTM D621 | 3% ( 1500psi-24hr. RT ) |

| Specific Gravity ASTM D792 | 1.95 |

| DESIGN CRITERIA RULON® 1045 | |

|---|---|

| Temperature - Typical Range F0 ( c0) | -400/+550 (-240/+288)* |

| Maximum PV [ Continuous)(MPa*m/s) | 1 o.ooo (0. 35)* |

| Maximum P - psi ( Static )(Mpa) | 1000 (6.9)* |

| Maximum V- SFM [ No load) (m/s) | 400 (2)* |

| Shaft Hardness - Minimum | Rc25 |

| Shaft finish recommended Ra µin(µm) | 8 -16 (0.2-0.4)* |

| Shaft Material | Stainless to Hardened Steel | ENGINEERING INFORMATION |

| Friction - Static & Dynamic | 0.10- 0.20 |

| Flammability ASTM D635 | Non-Flammable |

| Chemical Resistance | Data Available |

| Linear Coefficient of 78"-300"F Thermal Expansion [ 26" to 149" C I x1 0-5in/in"F [ x10-5m/m"C I | Diameter 5. 2 (9. 3)* Length 6. 8 (12. 2)* | PHYSICAL DATA |

| Elongation ASTM D4894 | 450% |

| Tensile Strength ASTM D4894 [MPal | 3900 psi (26.9)* |

| Specific Gravity ASTM D792 | 2.11 |