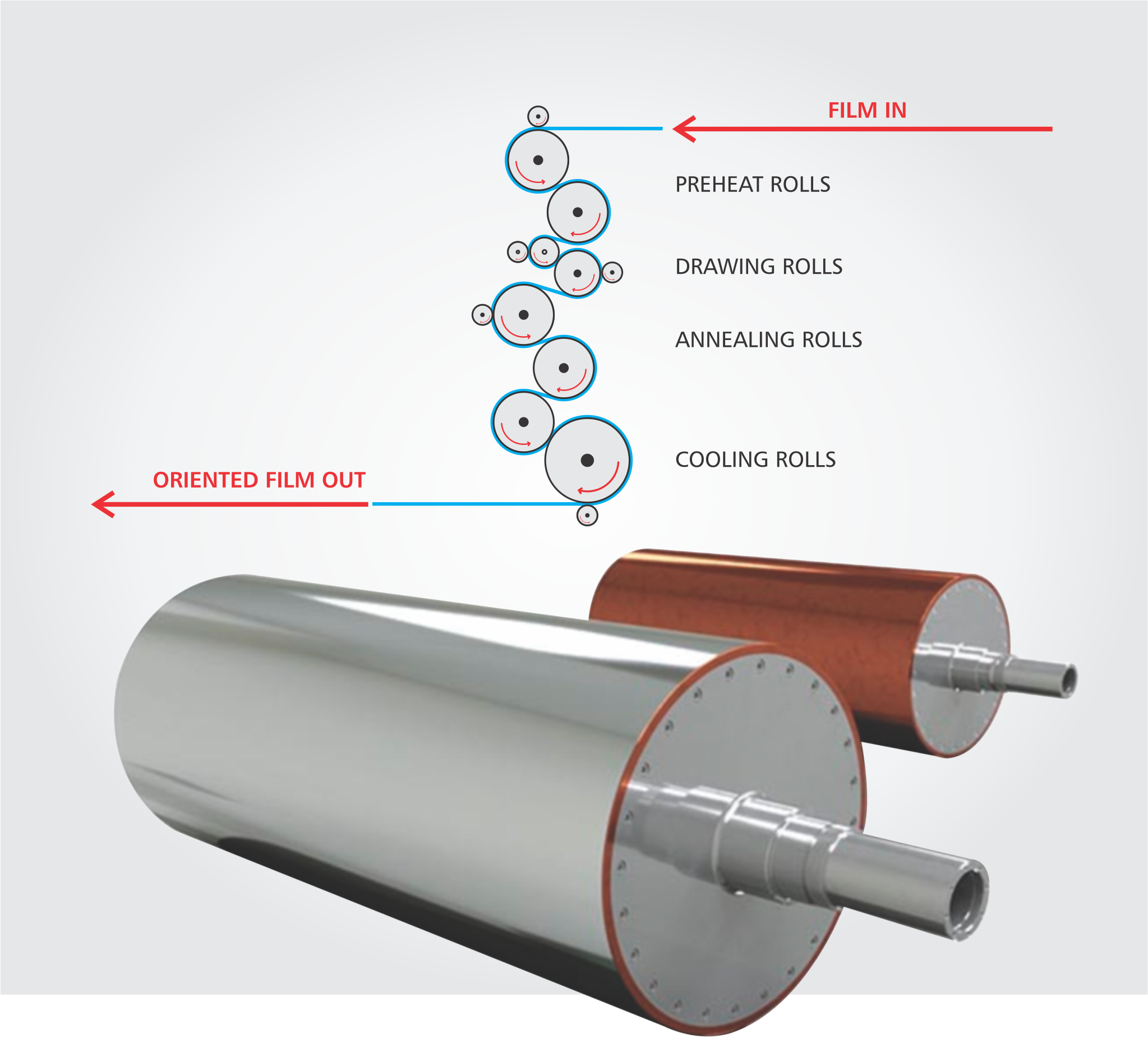

This is part of MDO. These infrared heaters are installed for the purpose of stretching the film in direction i. e. Machine Direction Orientation.

The film's surface tension is an important factor in all these applications as it is a measure of the wettability and printability of a film surface. To improve these characteristics of their product, manufacturers subject freshly produced films to a corona treatment to optimize surface treatment.

Plastic film are produced in VARIOUS widths in the production of BOPP / BOPET films and require specialized treatment systems able to deliver consistently high power levels over large electrode widths.

Material surfaces are treated with the plasma generated by a dielectric barrier discharge (DBD) to increase their surface energy. An increase in surface energy leads to an increase in the adhesive forces exerted by the surface, which is a major advantage for printing, laminating and other processes. This effect is therefore used frequently in the production and converting of plastic films and other substrates.CORONA treatment unit for STRETCHLINE film manufacturers shall be selected having corona treatment technology, today's most popular and effective one. They have been proven and specialized in the production of these treatment systems for decades.

Also, there are corona treatment solutions are available in Europe and also in India, which are quite competitive.

All electrical systems, controls and allied automation is used that of from SIEMENS, Germany which is one of the best and proven system. (It can also be available from • SCHNEIDER ELECTRIQUE, France.)