'FOURWENTS' HAS EARNED THE REPUTATION AS AN INNOVATOR AND INDUSTRY LEADER IN THE MANUFACTURING OF FEED SCREWS, SCREW TIPS BARRELS AND OTHER PRECISION COMPONENTSWHETHER IT'S NEW, A REBUILD, OR A REPAIR. YOU CAN BE SURE OF QUALITY AND PERFORMANCE THAT WILL IMPROVE PRODUCTION.

AT 'FOURWENTS' WE STRIVE TO EXCEED CLIENT EXPECTATIONS ON ALL PRODUCTS AND SERVICES COMPREHENSIVE PRE-PLANNING ENSURES ALL WORK IS DONE IN THE MOST EFFICIENT AND COST-EFFECTIVE MANNER, DETAILED POST-MANUFACTURING INSPECTIONS ASSURE PRODUCTS LEAVE OUR FACILITY READY FOR TROUBLE-FREE PERFORMANCE WE ARE SO CONFIDENT IN THE SUPERIOR QUALITY OF OUR PRODUCTS AND SERVICES THAT WE PROVIDE A WARRANTY ON MATERIALS AND WORKMANSHIP.

AISI 4140. AISI 4340. 17-4 PH STAINLESS STEEL, NITRIDING STEELS, D-2 TOOL STEEL, H-13. CPM 9V ETC..

FLAME HARDENING, HEAT TREATING, INDUSTRIAL HARD CHROME PLATING. ELECTRO LESS NICK CARBIDE COATING AND HARD FACING.

COLMONOY 56 & 83, STELLITE 6 & 12

135M NITRALLOY, D-2, 10V, BIMETALLIC WITH HIGH WEAR RESISTANT LINERS

ALL OUR PRODUCT ARE MANUFACTURED IN-HOUSE ON COMPUTERIZED MACHINES UNDE SUPERVISION OF QUALIFIED ENGINEERS OUR EXPERIENCE WITH A WIDE VARIETY OF MANUFACTURERS EQUIPMENT, COUPLED WITH A

WELL-KNOWN AND RESPECTED PROCESS, ENGINEERING AND MANUFACTURING CAPABILITY,

POSITIONS 'FOURWENTS' TO PROVIDE YOU WITH THE HIGH LEVEL OF SERVICE AND PERFORMANCE

REQUIRED IN TO DAY'S DYNAMIC BUSINESS ENVIRONMENT.

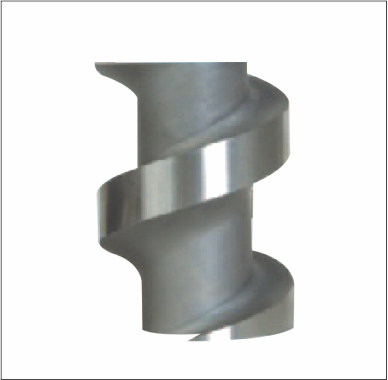

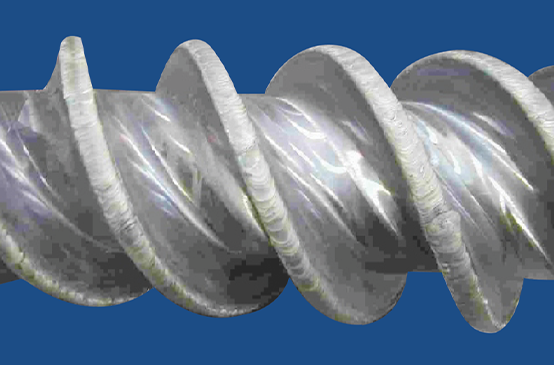

'FOURWENTS' CAN PROVIDE EXTRUSION SCREWS AND BARRELS. FOLLOWING IS OVERVIEW

OF PRODUCTS AND SERVICES AVAILABLE FORM 'FOURWENTS'

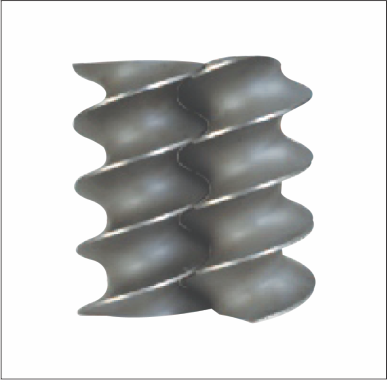

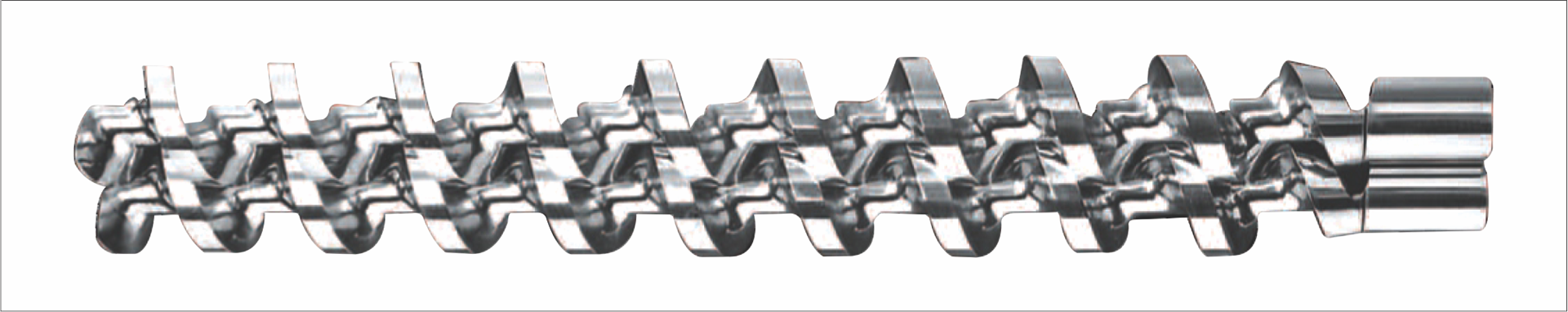

EXTRUSION SCREWS & BARRELS

SCREW & BARREL SERVICES

25 MM TO 300 MM DIAMETER

UP TO 6600 MM LENGTH IN PIECE CONSTRUCTION

COMMON AND EXOTIC MATERIALS

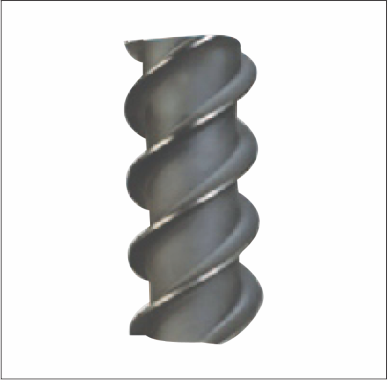

MULTIPLE FLIGHT CONFIGURATIONS

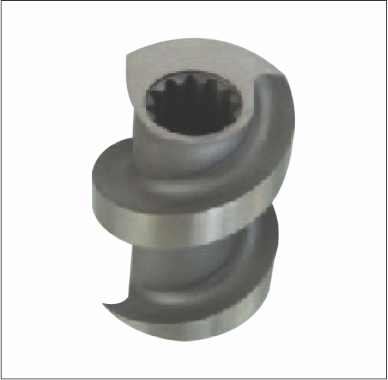

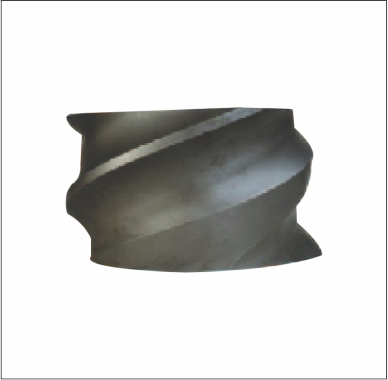

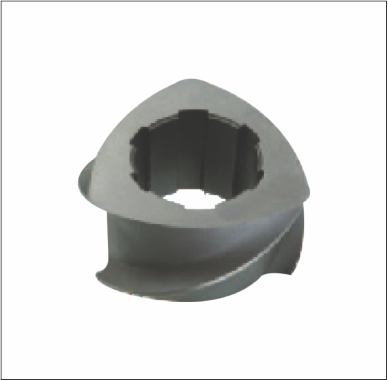

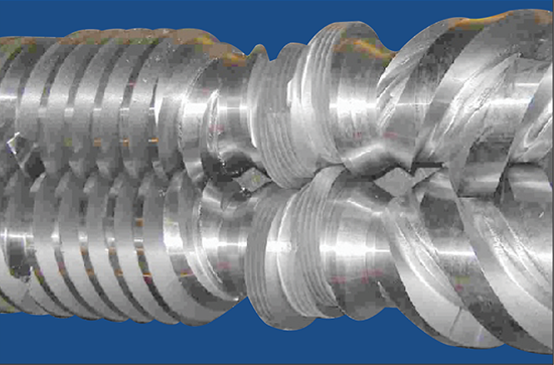

DISTRIBUTIVE AND DISPERSIVE MIXERS

HARD FACING AND ENCAPSULATION

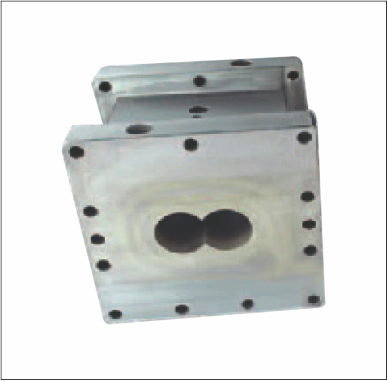

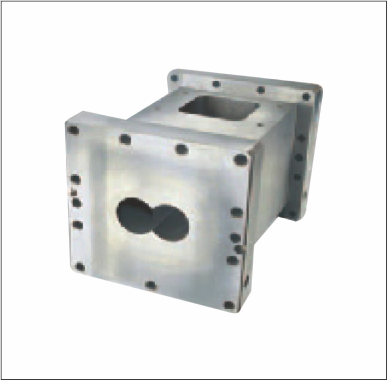

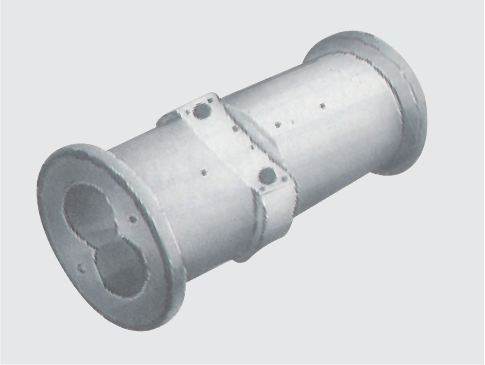

BARREL SECTIONS

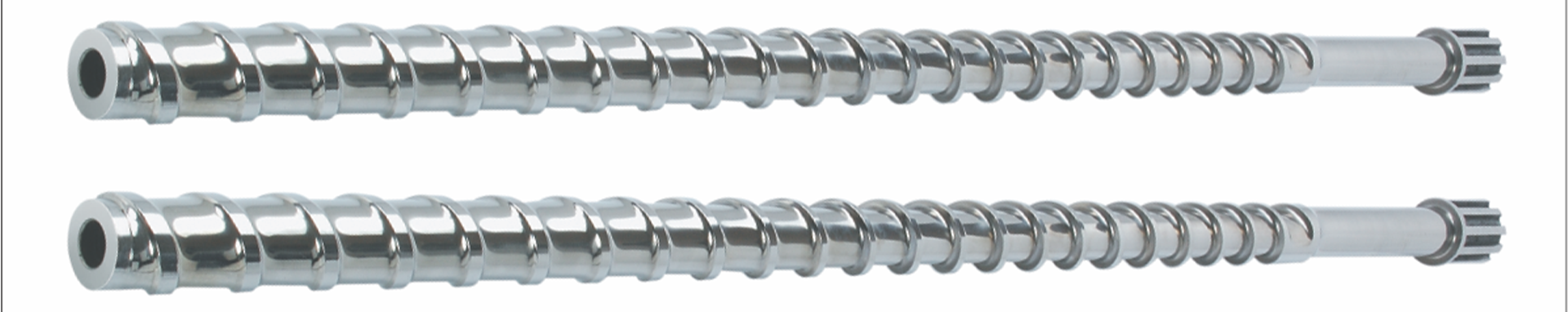

TANGENTIAL SCREWS

SHAFTS FOR INTERLOCKING MACHINES HARD FACING AND ENCAPSULATION

CUSTOM DESIGN SCREWS AND BARRELS

NEW BARRELS WITH BIMETALLIC LINERS

REPAIR BROKEN SCREWS

ADD MIXING SECTIONS

REBUILD I REPLACE SCREW TIPS I VALVES

ADD PARTIAL SLEEVE IN BARRELS

RELINE FEED SECTION

MANUFACTURE NEW SCREWS

REBUILD SCREWS WITH HARD SURFACING

CHANGE FLIGHT WIDTH

HONE BARRELS m NEXT UNIFORM SIZE ADD PRESSURE TRANSDUCER HOLES ON-SITE MEASUREMENT AND INSPECTION

25 MM TO 125 MM DIAMETER

HSS SLEEVES FOR HARD COMPOUNDING

EN 41 - B NITRIDED SLEEVES FOR SOFT COMPOUNDING

HARDNESS IN THE RANGE OF 65-68 HRC

ALL MATCHING FACES ARE GROUND & LAPPED PARALLEL

MATERIALS TO BE PROCESSED

OUTPUT DESIRED

SCREW DIAMETER PREFERRED WITH lYPE OF CONSTRUCTION, SINGLE, TWIN, SEGMENTED ETC.

L I D RATION DESIRED

lYPE OF BARRELS PREFERRED, NITRIDED, BIMETALLIC ETC

COMPLETE DIMENSIONAL DRAWINGS I BLUE PRINTS