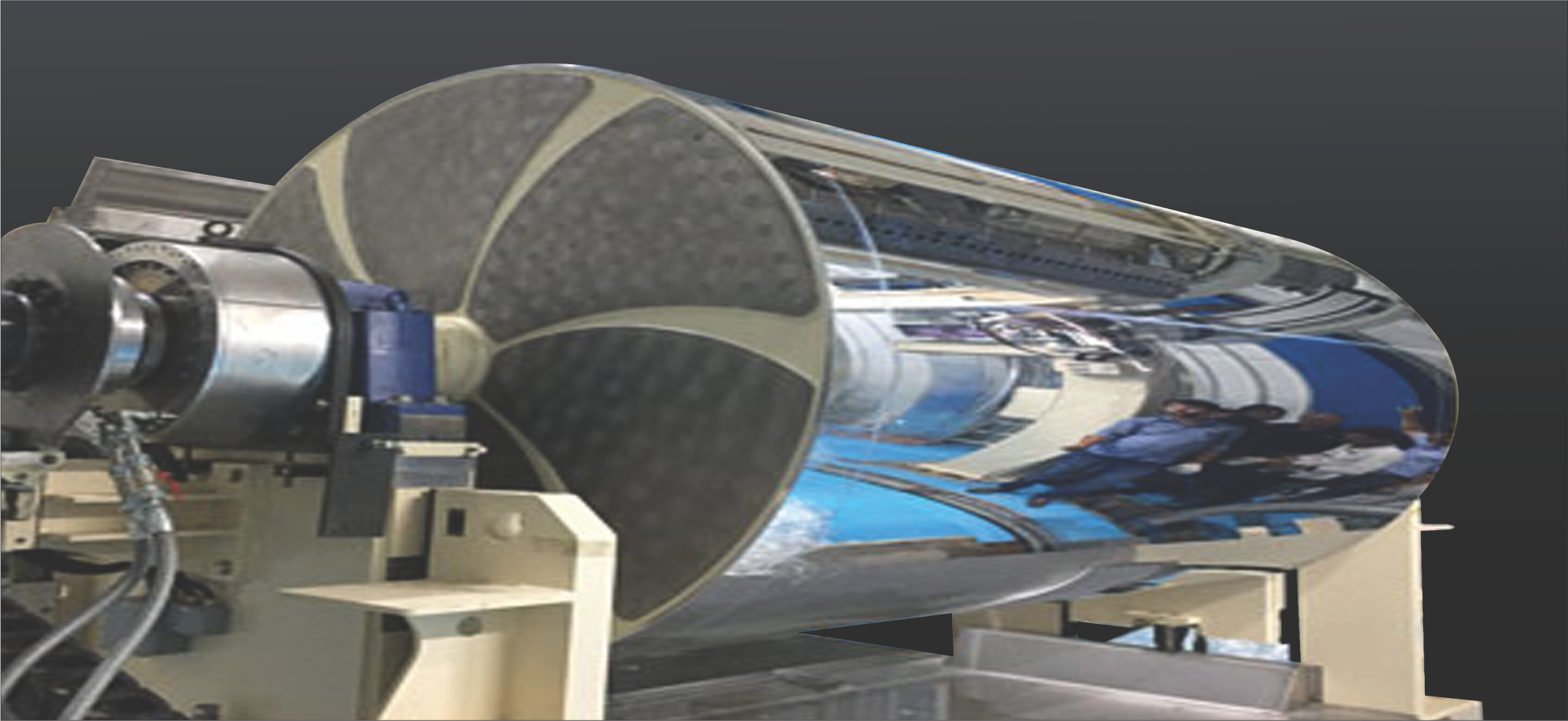

ROLLERS: Rollers with thermal exchangers, Chill rolls, Calendar rolls, Optimum cast rolls, Preheating rolls, Stretching rolls, Heating rolls, Cooling rolls, Corona rolls, Flame treatment rolls.

ROLLERS: Rollers with thermal exchangers, Chill rolls, Calendar rolls, Optimum cast rolls, Preheating rolls, Stretching rolls, Heating rolls, Cooling rolls, Corona rolls, Flame treatment rolls.

KNOW-HOW AND SKILLS:

SURFACE TREATMENTS:

QUALIFICATIONS OF THE MANUFACTURER:

The manufacturer shall be amongst world's most trusted and proven alternatives holding effective QMS of similar to ISO 9001-ISO 14001-EN9100C